Water Well Cleaning

By Mike Guardino

Why do so many get it wrong?

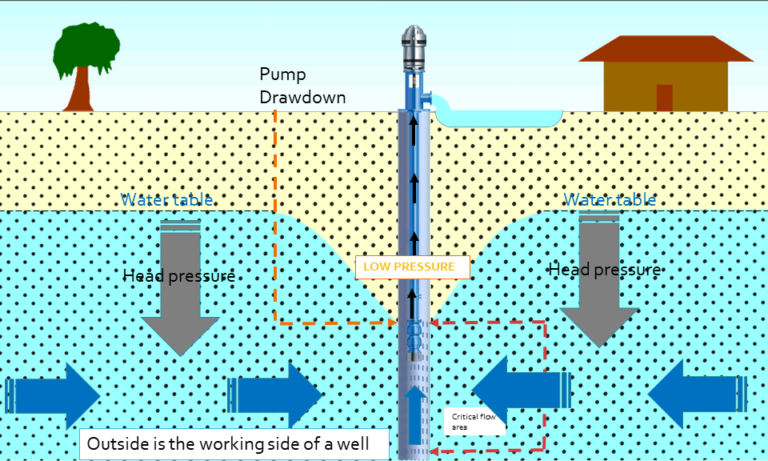

A low producing water well is seldom caused by clogging or plugging. Clogging backs up exiting water slowing it down and plugging changes how water enters a well. The difference is wells have water height outside to speed water up to go around obstacles. To understand this place your thumb over a garden hose and try to stop water from passing. The water volume is forced around the obstruction by water pressure. Low production only occurs in water wells when water height outside or gravity can’t create enough inflow pressure to move water in as fast as it is being taken out.

Scale and encrustation

The only time heavy scale or encrustation can slow production is if a well sits idle for a long time. This is because water has stopped moving and there is no water table pressure to keep flow area open. The reason a well keeps volume with buildup on the casing is as buildup grows so does inflow pressure. When there is not enough entrance area water will wear out perforations, develop a hole or even break the casing to keep flow rate up. It is the thumb over the hose, the more you close off area the more friction and weight pushing in.

Well plugging

We can’t see outside where a well slowly plugs over time and there is little indication that it is occurring. Plugging is the formation squeezing down, debris build up or anything that reduces flow space outside. There are two sides to every well, the low pressure side where water is collected and the high pressure side where the water supply is, and it is the pressure difference that moves water into a well. The low pressure side is the well’s non-working side, a pump lowers water and water flows in. The high pressure side is where the work takes place. Lowering water inside increases pressure outside, but to create volume their needs to be enough water table height and enough flow space for pressure to push volume through. What plugging does is reduces flow space and rises pressure, this means we get less water for every inch of pump drawdown inside.

It is best to clean to prevent problems

Sand pumping, contamination and almost all well casing damage is from reducing flow space and increasing pressure. It is not the amount of water being pumped that wears out a well it is how hard a well works to produce it. Today we like to pump wells hard and fast without the cost of cleaning them until they lose water and that is why wells develop pumping issues. It is important to clean a well to save it after it loses production, but it is best to clean to prevent problems from ever starting. The problem with most well cleaning is they don’t go far enough or are on the wrong side of the pipe. It is good to clean the non-working side, even if it is just to get to the outside. It is the working side where the water supply is, that is most important. It is just that simple the more space that is freed up outside the more water you get inside.

Cleaning the working side of a well

There are many ways to clean wells, but to get good results we need to pay attention to science not unclogging theories. Well cleaning is not done to make a well look good it is done to make a well pump more or better water. The goal should be water efficiency, that is get more water in for every inch the water is lowered inside. Well cleaning is a pressure problem and it takes both pressure and chemistry to clean outside where the supply is located. Using CO₂ is a good example, it is safe and effective, but needs to be done right along with pre-cleaning or it is a waste of time. The cleaning energy in CO₂ comes from cold boiling, sublimating a solid into a pressurized gas. CO2 is powerful energy and chemical friendly and when properly used together out in water producing zones it frees up the water bearing strata, that we need to get a bigger supply.

Sacramento Office

Bob

Tel. 916 765-5221

Email: waterwellbob@gmail.com

Bakersfield Office

Mike

Tel. 916 779-0553

Email: wellboyh2o@gmail.com